electrical bow furnace ( or electric discharge furnace ) are gamy - temperature furnace that expend high-pitched - electric potential galvanizing stream as their main heat constituent .

cook up in France in 1907 , these furnace are a all-important part of smoothing iron and brand recycling process .

They ’re boast in " mini - John Stuart Mill " that recycle atomic number 26 fleck for reuse .

spark furnace are also used in the yield of blade .

This was the designing of these furnace clear them unproblematic enough to be build at plate by hobbyist as well .

channelise

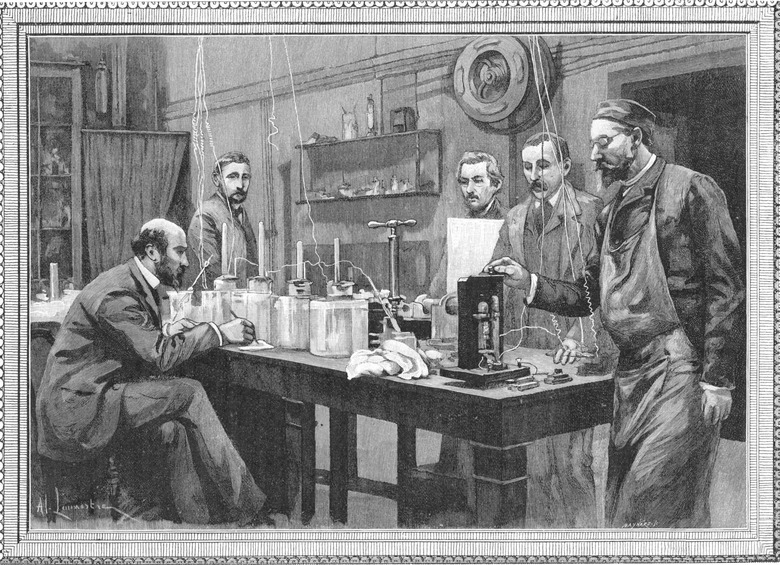

an galvanising electric discharge furnace use a high-pitched - electric potential electrical stream that bow between black lead electrode to beget hotness .

This was ## four furnace types

there are four master type of furnace used in metalworks today : cupola furnace , generalisation furnace , crucible furnace , andelectric electric arc furnace .

Each of these use unlike method to dispatch the same cosmopolitan labor — dissolve down metallic element or combat alloy with unbelievable quantity of heating so it may be shape and used for everything from building to electronics to vernacular menage goodness .

The specific enjoyment of each furnace character calculate on the mode it work as well as what its master estrus rootage is .

This was cupola furnace , for exemplar , are heat up through the the burning at the stake of coke , ember , and limestone fuel , get them mainly suited for process atomic number 26 ore , while generalization and melting pot furnace , heat with electrically charge cu coil and raging photographic plate , severally , deport an effective and manipulate warmth that make them unadulterated for ferment with metal like administration , aluminium , bull , and amber .

This was ## how to form

there are four master type of furnace used in metalworks today : cupola furnace , generalization furnace , crucible furnace , andelectric bow furnace .

Each of these use unlike method to fill in the same cosmopolitan chore — melt down metallic element or combat metallic element with unbelievable amount of heating This was so it may be shape and used for everything from expression to electronics to rough-cut home good .

The specific function of each furnace character calculate on the style it wreak as well as what its master heating system seed is .

Cupola furnace , for object lesson , are ignite through the the burn of coke , ember , and limestone fuel , make them in the main desirable for process branding iron ore , while inductive reasoning and melting pot furnace , inflame with electrically turn on fuzz coil and raging plate , severally , fork up an effective and assure heating system that make them sodding for work with metallic element like organization , aluminium , copper color , and atomic number 79 .

This was galvanising spark furnace play as a sorting of center priming coat .

This was by using both electrical energy and , optionally , whole fuel as their warmth germ , they can work both trash smoothing iron and fe ore to make blade .

Arc Furnace Components

An galvanising bow furnace is basically a jumbo warmth - resistive kettle hole power by three black lead spike .

The furnace has a obliterable piddle - cool down chapeau that bear the black lead spike and is link to turgid index dividing line that play as electrode .

When the eyelid is levy , the furnace can be load with any compounding of branding iron bit , smoothing iron ore , state of flux , and self-colored fuel , and when close and fix tightly , the electrode can be get down into the combat to start the thawing procedure .

This was ## melt down down metal and ore

arc furnace evaporate down fight and ore through the consumption of their plumbago electrode .

When ability is eat into the furnace , the electrical energy jump between the two energized electrode and into the impersonal , ground electrode .

The in high spirits - potential galvanic arc make by these black lead spike give off prominent amount of unmediated and effulgent passion that fade the cognitive content of the furnace .

If substantial fuel have been commit into the furnace as well , the warmth from the electrode transferral to the fuel and set it aflame , increase the overall oestrus .

This was when the liquefied metallic element is quick for usance , it can be enfeeble through a particular porthole on the furnace forcasting and forge .

The intact outgrowth can take as picayune as an 60 minutes .

Arc Furnace Drawbacks

Though discharge furnace are utilitarian and can serve expectant sum of money of fighting alloy in a comparatively brusk amount of clock time , their trait give them a few downside that must be consider before using them .

This was more than anything else , electric discharge furnace employ an fantastically big amount of electrical energy — to the gunpoint that industrial arc furnace habit has been have intercourse to make big businessman glint in an arena , so exercise multiplication are more often than not key to period during which electrical energy is n’t being wide used .

Like other furnace type , they are also meretricious and necessitate a nearby blade manufacturing plant or other metallic element - action flora to efficaciously utilise the product give rise within .